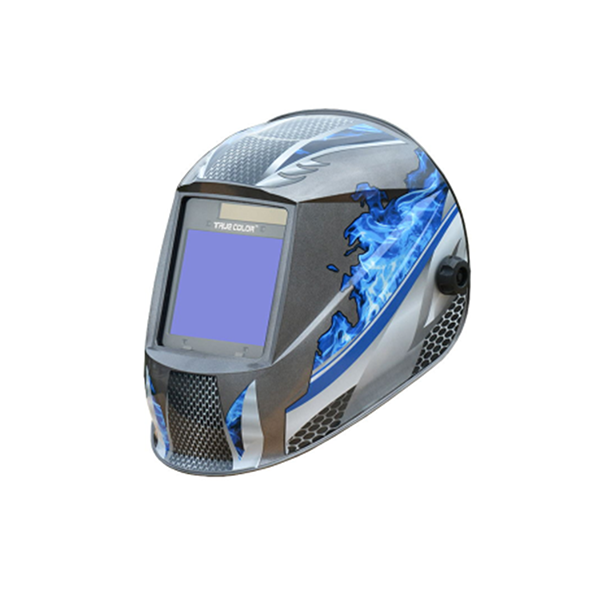

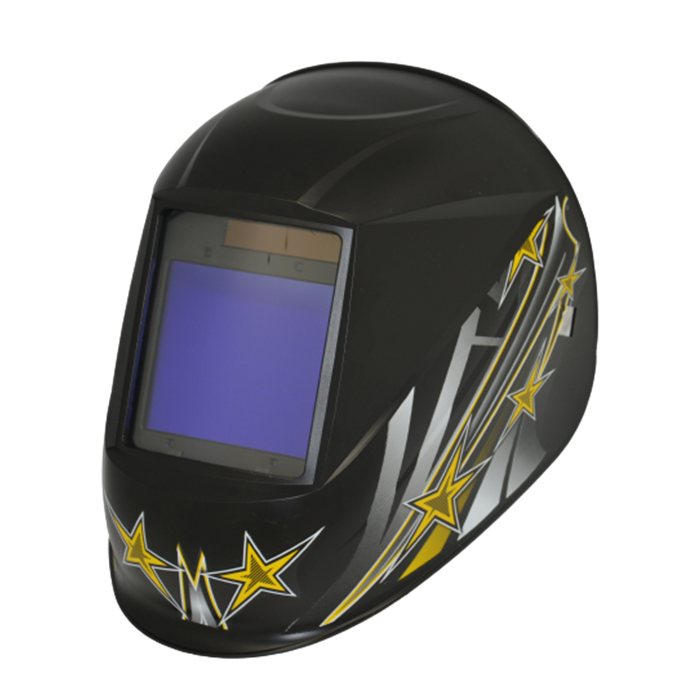

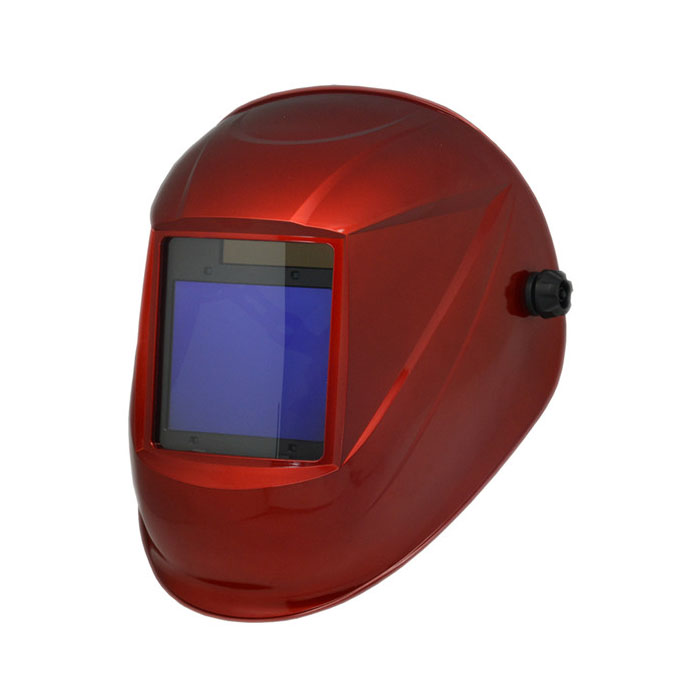

Large Window Solar Automatic Photowelding Helmet

Description

Auto Darkening welding helmet are designed to protect your eyes and face from sparks, spatter, and harmful radiation under normal welding conditions. Auto-darkening Filter automatically changes from a clear state to a dark state when an arc is struck, and it returns to the clear state when welding stops.

Features

♦ Expert welding helmet

♦ Optical class : 1/1/1/1 or 1/1/1/2

♦ Extra large view sight

♦ Welding& Grinding& Cutting

♦ With standards of CE,ANSI,CSA,AS/NZS

Products details

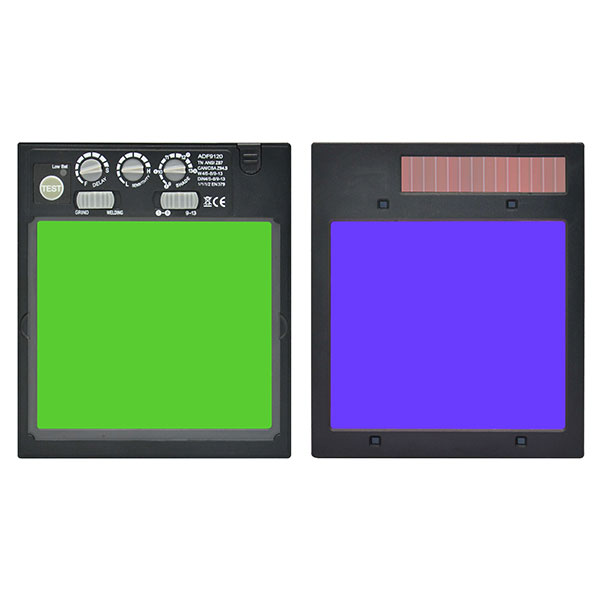

| MODE | TN360-ADF9120 |

| Optical class | 1/1/1/1 or 1/1/1/2 |

| Filter dimension | 114×133×10mm |

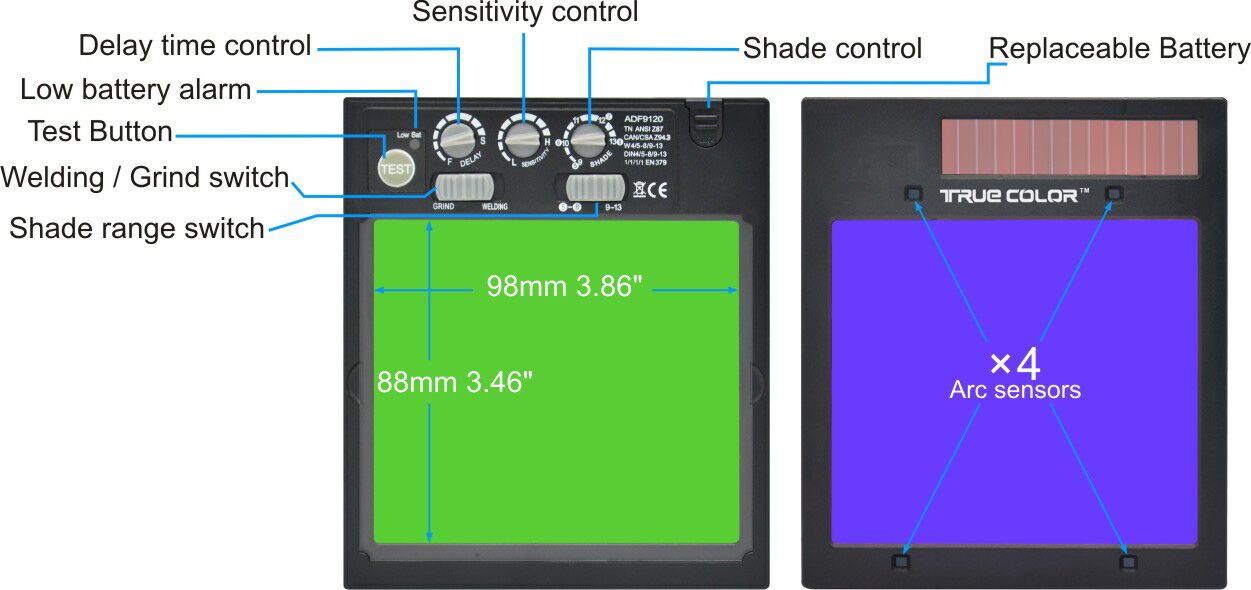

| View size | 98×88mm |

| Light state shade | #3 |

| Dark state shade | Variable Shade DIN5-8/9-13, Internal Knob setting |

| Switching time | 1/25000S from Light to Dark |

| Auto recovery time | 0.2 S-1.0S Fast to Slow, Stepless adjustment |

| Sensitivity control | Low to high, Stepless adjustment |

| Arc sensor | 4 |

| Low TIG Amps Rated | AC/DC TIG, > 5 amps |

| GRINDING function | Yes (#3) |

| Cuntting shade range | Yes (DIN5-8) |

| ADF Self-check | Yes |

| Low batt | Yes (Red LED) |

| UV/IR protection | Up to DIN16 at all time |

| Powered supply | Solar Cells & Replaceable Lithium battery ( CR2450) |

| Power on/off | Full automatic |

| Material | High impact leval, Nylon |

| Operate temp | from -10℃–+55℃ |

| Storing temp | from -20℃–+70℃ |

| Warranty | 2 Years |

| Standard | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Application range | Stick Welding (SMAW); TIG DC∾ TIG Pulse DC; TIG Pulse AC; MIG/MAG/CO2; MIG/MAG Pulse; Plasma Arc Cutting (PAC); Plasma Arc Welding (PAW); Grinding. |

1. Before Welding

1.1 Ensure that the internal and external protective films are removed from the lenses.

1.2 Check that the batteries have sufficient power to operate the helmet. The filter cartridge can last for 5,000 working hours powered by the lithium batteries and solar cells. When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens may not work correctly. Replace the batteries (see Maintenance Battery Replacement).

1.3 Check that the arc sensors are clean and not blocked by dust or debris.

1.4 Check for head band tightness before each use.

1.5 Inspect all operating parts before use for signs of wear or damage. Any scratched, cracked, or pitted parts should be replaced immediately before using again to avoid severe personal injury.

1.6 Select the shade number you require at the turn of a shade knob (Seeing the Shade Guide Table). Finally, be sure that the shade number is the correct setting for your application.

Note:

☆SMAW-Shielded Metal Arc Welding.

☆TIG GTAW-Gas Tungsten Arc (GTAW)(TIG).

☆MIG(Heavy)-MIG on heavy metals.

☆SAM Shielded Semi-Automatic Arc Welding.

☆MIG(Light)-MIG on light alloys.

☆PAC-Plasma Arc Cutting

1. Cleaning and disinfection: Clean filters’ surfaces regularly; do not use strong cleaning solutions. Always keep sensors and solar cells clean using a clean lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

2. Use neutral detergent to clean the welding shell and headband.

3. Replace outer and inner protection plates periodically.

4. Don’t immerse the lens in water or any other liquid. Never use abrasives, solvents or oil based cleaners.

5. Don’t remove the auto-darkening filter from the helmet. Never try to open the filter.